Yes-Sun Environment Biotech Co.,Ltd

Pioneer in Organic waste treatment-Composting-free Technology, retrieving the organic life cycle in nature

Core concept: Environmental protection, giving back to society, and making profits

I was reminded of a quote from the renowned host Oprah Winfrey during my conversation with Yes-Sun.

Yes-Sun was established in 1998 by Mr. Shing-Hong Lee, who has over 30 years of experience representing professional medical instruments and devices in various countries. Mr. Lee firmly believes that the deteriorating environment can be restored through a medical approach, and businesses must prioritize environmental protection and their contribution to society alongside pursuing profits.

Amidst the global warming crisis and ongoing debates on environmental protection, Yes-Sun is guided by the principle of “giving back to society.” The company’s objective goes beyond maximizing profits for shareholders; it strives to be a responsible business and a member of the “Social Enterprise.” Yes-Sun is dedicated to making a positive impact on the general public and environmental preservation.

Achieving a win-win situation by simultaneously protecting the environment and fostering the company’s development is a core principle embraced by Yes-Sun.

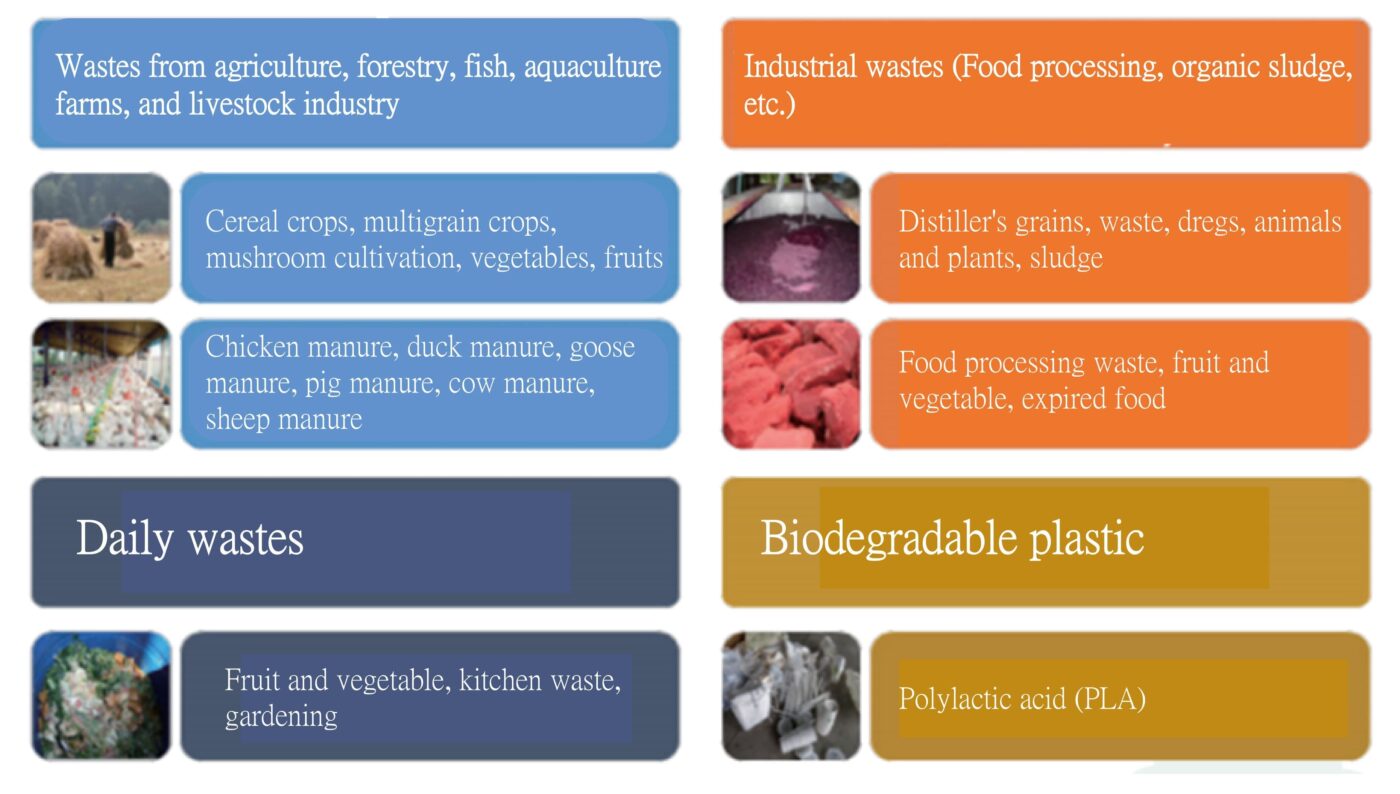

Yes-Sun recognizes the detrimental secondary pollutions caused by organic waste processing in various countries, posing risks to both the environment and human health. Consequently, Yes-Sun prioritizes the effective utilization of organic waste’s regenerative value and endeavors to transform waste into valuable resources.

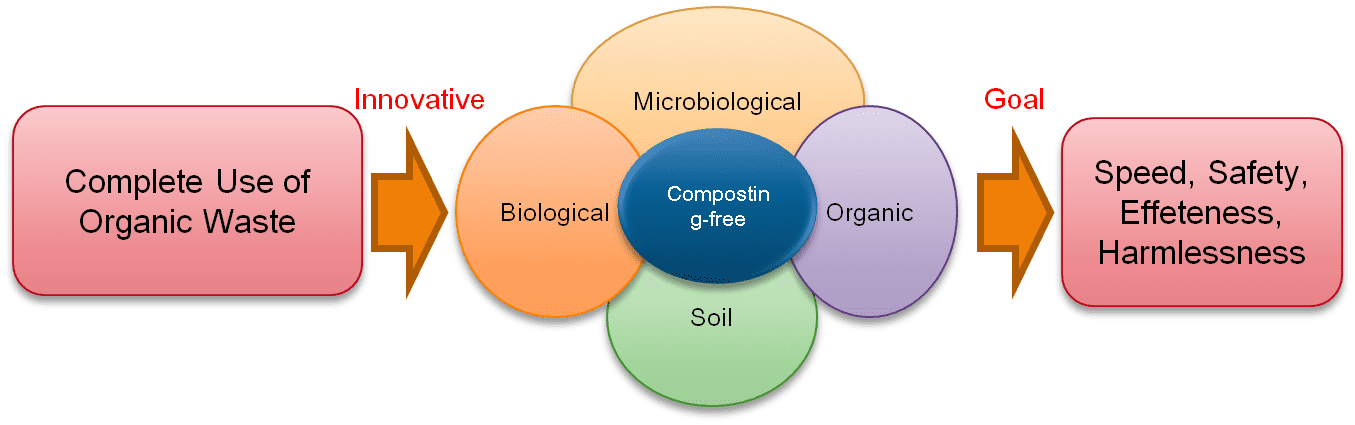

To achieve this goal, Yes-Sun has assembled a formidable research and development team comprising experts from diverse fields such as biochemistry, soil science, botany, environmental engineering, medication, and animal science. This multidisciplinary approach, combined with CEO Lee’s expertise in the medical instruments and devices industry, has led to the successful development of innovative hardware equipment and practical solutions, namely the “Composting-free technology” and “Composting-free equipment.” These breakthroughs have garnered international recognition with multinational patents and trademarks.

Yes-Sun’s management concept revolves around constant innovation and staying ahead of the competition. Striving to be one of the global leaders in technology and products, Yes-Sun not only excels in bio-technology development but also takes pride in its commitment to environmental protection. The company envisions the “Composting-free technology” as a viable solution for the reutilization of organic waste and a valuable contribution to mitigating global warming. As a responsible member of the global community, Yes-Sun is dedicated to minimizing environmental pollution, pursuing its goal with unwavering determination.

What is “Composting-free technology”?

◎Applications of Carbon Sequestration of Composting-free Technology

In this study, a sample of 100 kg of kitchen waste was taken, assuming a water content of 80%. The kitchen waste underwent two different treatments: traditional composting with a 60-day stack period, and fast fermentation treatment for 3 days followed by a 30-day stack. A comparison was also made with composting-free technology, where 2 kg of a specific formula was added for 1 hour treatment, followed by drying for 3 to 24 hours. The resulting changes in dry matter and water ratio are presented in Table 1.

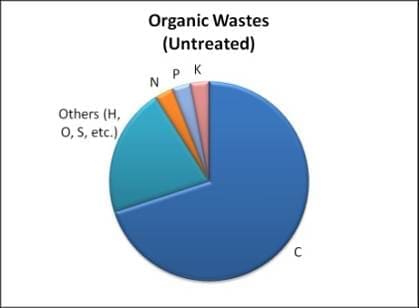

From Table 1, it is evident that both traditional composting and fast fermentation result in a significant loss of solid material, approximately 50% to 60%. This is due to the prolonged decomposition process carried out by microbes, which leads to the release of carbon dioxide into the air. Consequently, the recycled product retains only about 15% of the original input weight. In contrast, the Composting-free Technology process is much shorter, and by adding 1% to 2% of a specific formula (consisting of enzymes and additives), we can obtain 102% of wet fertilizer and 33% of dried fertilizer, respectively. Since the reaction period of the Composting-free treatment is only 1 hour, the option to transform the waste into wet fertilizer becomes viable. This reduces the duration and energy costs associated with drying. Therefore, in agricultural applications, the most cost-effective approach is to directly apply the wet fertilizer to the soil after treatment, thereby saving on drying and storage expenses.

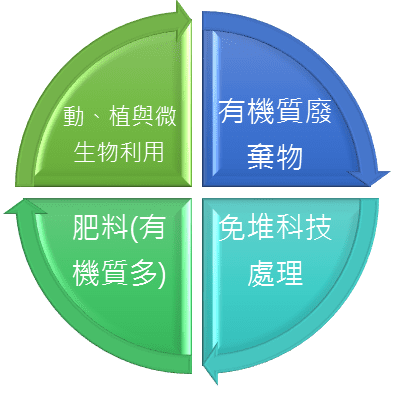

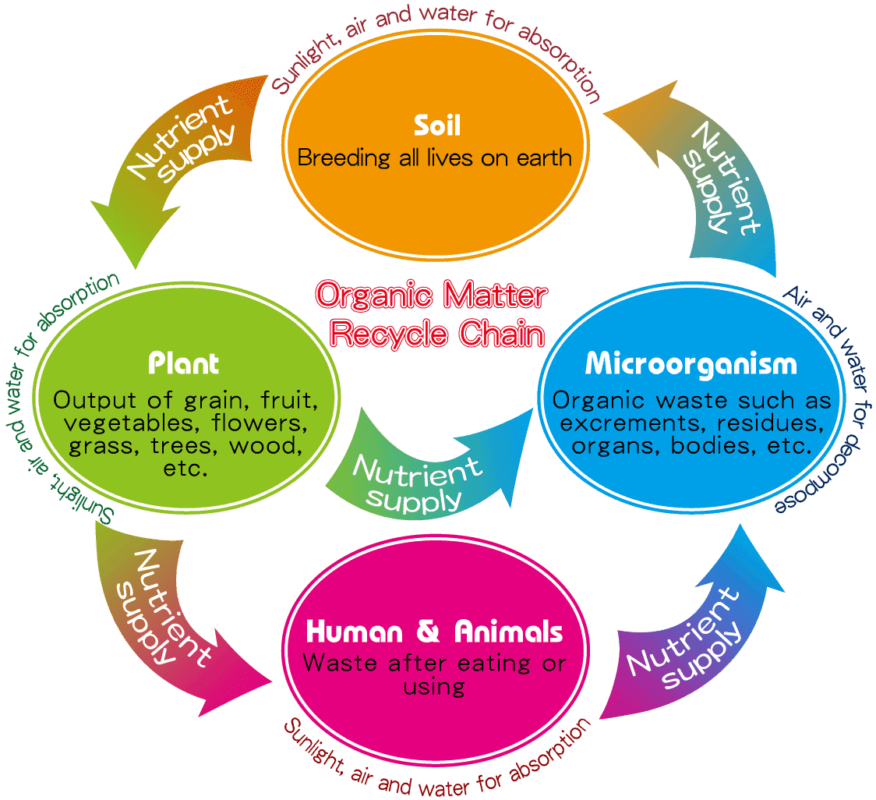

Ecological cycle chain- Zero waste in nature

Traditional treatment

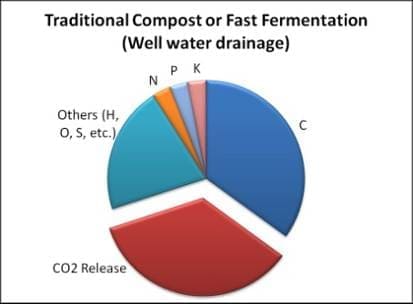

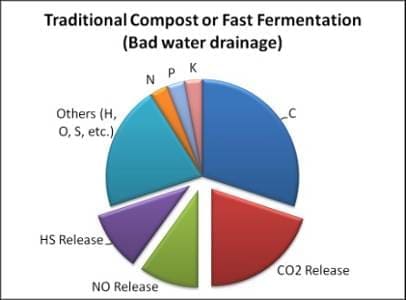

Traditional organic waste treatment is the use of composting or rapid fermentation, relying on microorganisms or strains to decompose organic matter, resulting that a massive loss of carbon content (approximately 50%~60%) in the waste .The process of decomposition is very time consuming (3-6 months), requires a large space and needs to be re-piled up frequently, and the process will cause odor, air and wastewater pollution.

Processing of Composting-free Technology

(1) High organic matter content in Composting-free Product

Composting-free Technology applies organic enzymes as catalyst to react in a short period, so there is no loss of carbon. As a result, the organic matter content of Composting-free end product is much higher than those from the traditional treatment methods.

(2) The C/N Ratio Remains Unchanged after Treatment

C/N ratio is a very important factor in the traditional compost field, people used it to judge the ripen status of the end products, but it is not a general rule. For examples, the C/N ratio of untreated soy flour is less than 20 of its C/N ratio, but it is not fully ripened. The C/N ratio of forest peat is greater than 20, but it is a stable end product. Furthermore, C/N ratio is not an essential factor to constitute the fertilizer, because the carbon content is not the element to affect the growth of crops. Composting-free Technology is capable to sequestrate the carbon in the end products, so the C/N ratio remains the same as in original wastes after treatment.

(3) The Carbon Footprint of the Composting-free End Product is lower than others

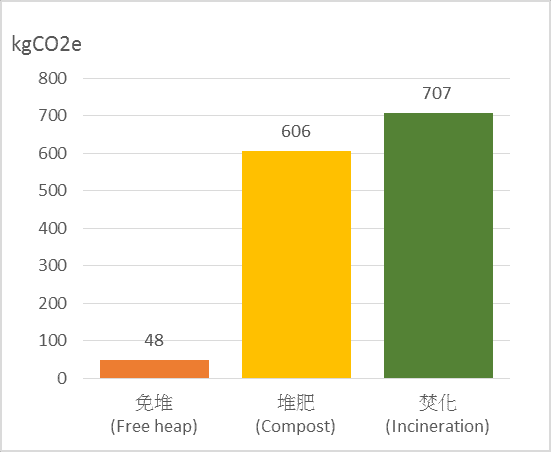

Yes-Sun participated in the 2016 SME energy conservation and carbon reduction counseling, which involved conducting a carbon footprint survey of the composting-free technology used to treat organic waste. The amount of waste disposal per ton of waste was analyzed and calculated, resulting in a carbon footprint of 48.306 kg CO2e for the composting-free service.

According to the Waste Incineration Plant data released by the Environmental Protection Administration, Executive Yuan, waste incineration treatment service has a carbon footprint of 606 kg CO2e per ton of waste. In the case of Southern Taiwan Science Park – Tainan Park, the carbon footprint is 707 kg CO2e per ton of waste. In the same functional unit, which is processing per ton of organic waste, the greenhouse gas emissions from Composting-free treatment are only 1/12 to 1/14 times that of incineration or burial disposal. This means that compared to incineration or burial treatment, the use of Composting-free technology for organic waste disposal can result in a reduction of greenhouse gas emissions by 92%.

Multi-application and examples of Composting free technology

◎Composting-free DIY fertilizer machine rapidly turns PLA into Organic fertilizer

The main materials of biodegradable plastics are starch, polylactic acid (PLA) and fiber protein. The contents of the biodegradable plastics do not contain traditional plastic components, and they are still comparable to traditional plastics in the use of enamel. Biodegradable plastics can be decomposed into carbon dioxide and water in the soil by aerobic microorganisms, water and oxygen in a polyoxic environment, and decomposed into carbon dioxide and methane by anaerobic microorganisms and H2O in a low oxygen environment.

Polylactic acid (PLA) is a raw material fermented from starch. It is mainly derived from plants. Although it can be biodegraded, it takes about 25 months to hydrolyze at room temperature, and it takes 11.4 months for bio-degradation to start. This is a shortcoming, even if it under good high temperature (60℃-70℃)and high water content(50-60%), it still takes at least 50 days to decompose, and it needs to be combined with specific temperature and humidity conditions to have a chance to completely decompose. However, using Yes-Sun Composting machine, organic waste can be converted into organic fertilizer in 90 minutes, solving the problem that PLA is not easy to handle.

Processing Example

- Processing capacity: 150L / batch

- Processing time: 90 minutes / batch

- Power consumption: three-phase 800W

- Fuel consumption: 105 K / batch (gas)

- Appearance size: width 85cm x depth 110cm x

height 150cm

▲、PLA tableware, the package is broken into pellets of about 5mm size

▲、The PLA is mixed with chicken manure to convert into organic fertilizer by using DIY fertilizer machine for 90 minutes.

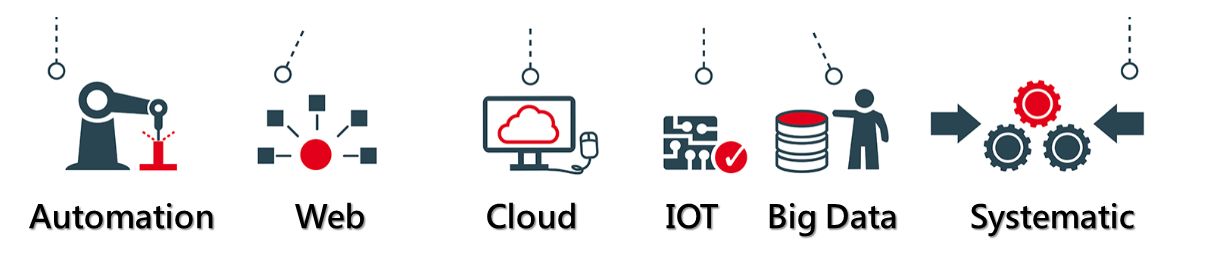

The combination of Ecological cycle chain and Industry 4.0

Yes-Sun’s products are also aligned with the advancements of Industry 4.0, incorporating IoT sensors into the system to record and monitor various operational parameters. These sensors, including environment temperature, material temperature, mixing speed, heating power, and other reaction parameters, enable real-time data transmission to a cloud server. The data is then analyzed in real-time, allowing for automatic adjustments to the operation parameters through software. This ensures that the enzymes are maintained in the optimal reaction condition throughout the entire process.

Yes-Sun’s perspective on sustainable business is rooted in the belief that long-lasting value can only be achieved by incorporating traditional beliefs and concepts into the enterprise’s business model. Recognizing that fierce market competition often leads to resource wastage and environmental pollution, Yes-Sun emphasizes that enterprises have a greater social responsibility to protect the natural ecology. Simply focusing on maximizing profits and shifting the costs onto society or the environment is not a sustainable approach.

Yes-Sun advocates for a shift in traditional values and the creation of new business operation rules. By adopting a broader perspective, the conflicts between economic development and environmental protection can be resolved. Yes-Sun firmly believes that the “Composting-free Technology” can contribute to striking a balance between economic development and environmental preservation, dispelling the myth that economic growth must come at the expense of the environment. It is irresponsible to pursue short-term gains at the cost of natural resources, and economic growth achieved through environmental degradation is not in the best interest of society as a whole.

To address these challenges, governments, enterprises, and communities must work closely together to make tangible contributions to environmental protection. By fulfilling individual responsibilities and collectively working towards environmental sustainability, we can become responsible members of the global community.

中文 (台灣)

中文 (台灣) Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt Bahasa Melayu

Bahasa Melayu Français

Français Español

Español Português

Português