Kitchen Treatment Demonstration

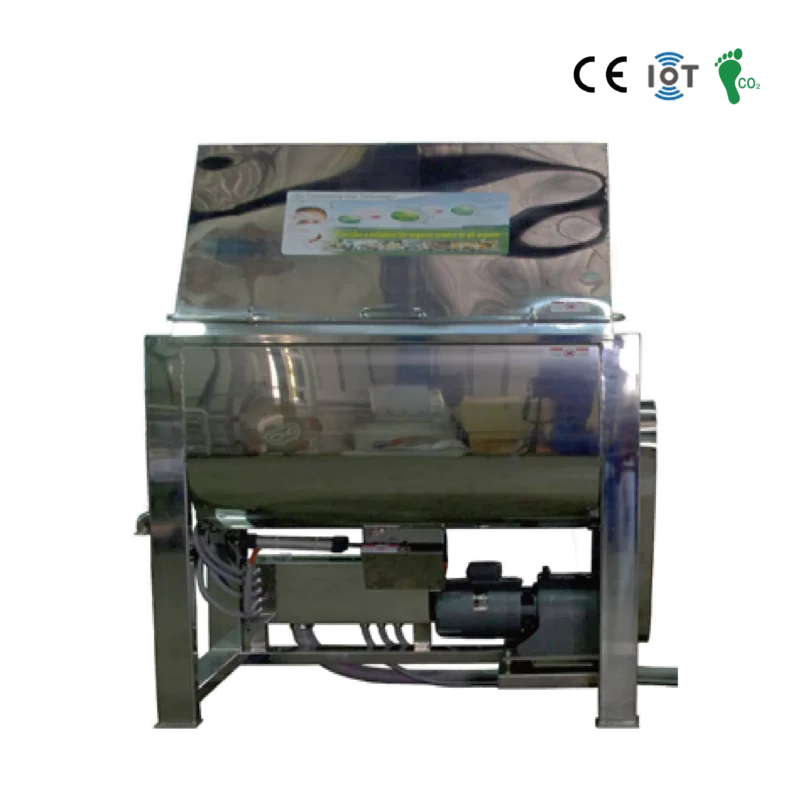

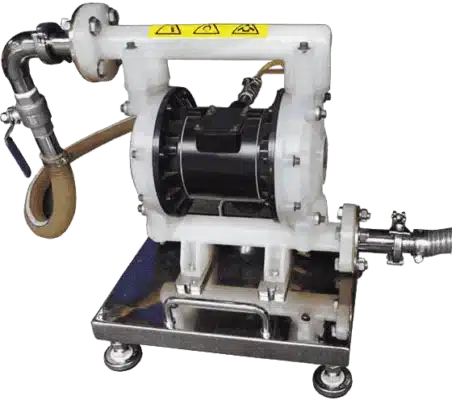

Commercial-type Equipment COM-400L

The simple and automatic design makes it suitable for small-scale treatment of food waste from communities, restaurants, and prisons, such as seafood, chicken, duck, mutton, and more.

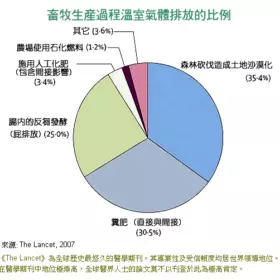

The degradation of food waste can often produce unpleasant odors, attract insects and pathogens, and cause pollution to the surrounding environment, posing a risk to people’s health. This system is also effective for processing animal dung and excrement, as well as other types of waste that require immediate attention and faster treatment.

中文 (台灣)

中文 (台灣) Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt Bahasa Melayu

Bahasa Melayu Français

Français Español

Español Português

Português