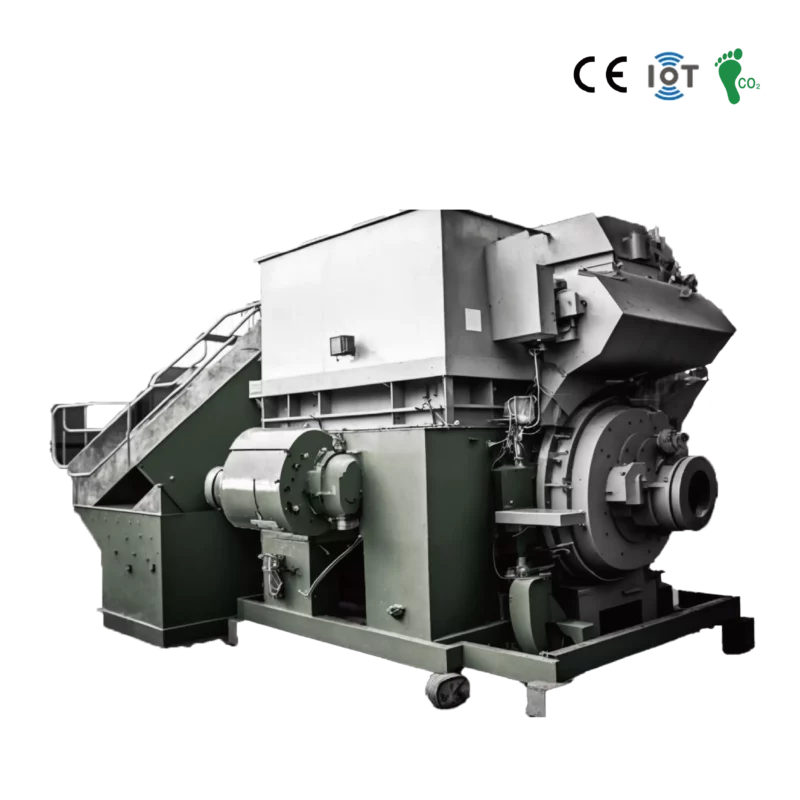

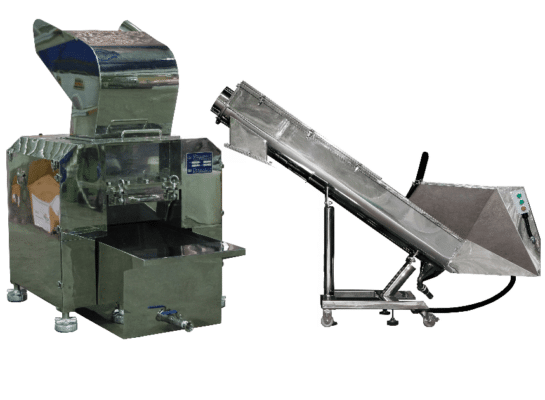

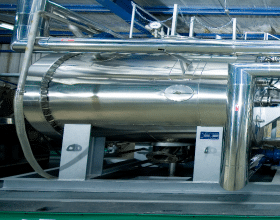

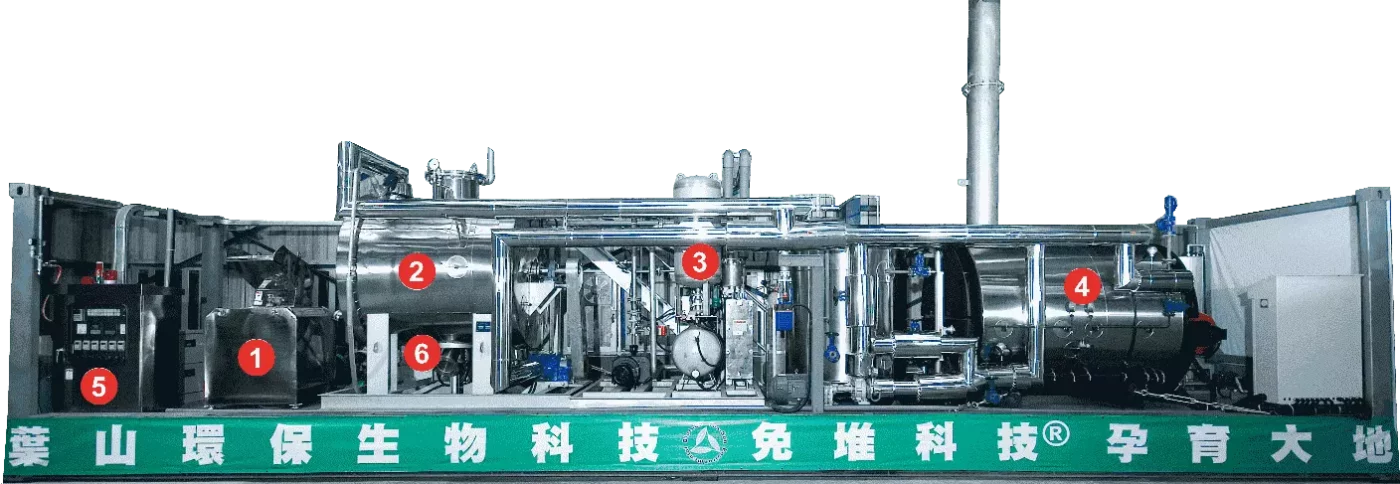

Standard-Type Equipment SUN-1500L

The largest composting-free technology system is designed for handling a wide range of organic waste treatment tasks and is suitable for use by both public and private agencies and industries. The system comes in two forms: a fixed type and a mobile type, depending on the specific needs of the user. With its large capacity and advanced features, this system is a powerful tool for managing organic waste on a large scale.

中文 (台灣)

中文 (台灣) Bahasa Indonesia

Bahasa Indonesia Tiếng Việt

Tiếng Việt Bahasa Melayu

Bahasa Melayu Français

Français Español

Español Português

Português